Employee Spotlight – PTC Chris

CHRIS ANDREWS – PTC Europe

In 2010, Chris began working part time at PRS Guitars Europe alongside running his own Guitar repair and refinishing business. After extensive training in San Diego California, Chris was awarded Platinum level repair status by Taylor Guitars and was also a recognised UK repair centre for Lowden, Parker Guitars and Solar Guitars. During this time, Chris also volunteered for the Musical Instrument amnesty Campaign fronted by the BBC. Repairing and refinishing hundreds of guitars for free. All of which made their way into Schools throughout the United Kingdom.

In 2017 Chris could no longer control the urge to join PRS Guitars Europe full time. With uncontrollable enthusiasm and record speed, he set to work designing and project managing the installation of an all new Spray booth refinishing area, which he now fronts.

1)What’s your typical day working in the PTC?

My days tend to vary, some days can be spent solidly repairing or setting up guitars and other days I am in the spray booth refinishing models.

Normally, I start my day checking on what’s been booked in and plan accordingly, working my way through the guitars. On completion, a work document is filled in, printed and attached to the guitar, this is then handed over to the warehouse team to process.

All refinishing work is set aside for me to examine and evaluate, a best course of action (especially if anything needs to be addressed prior to spraying) is documented.

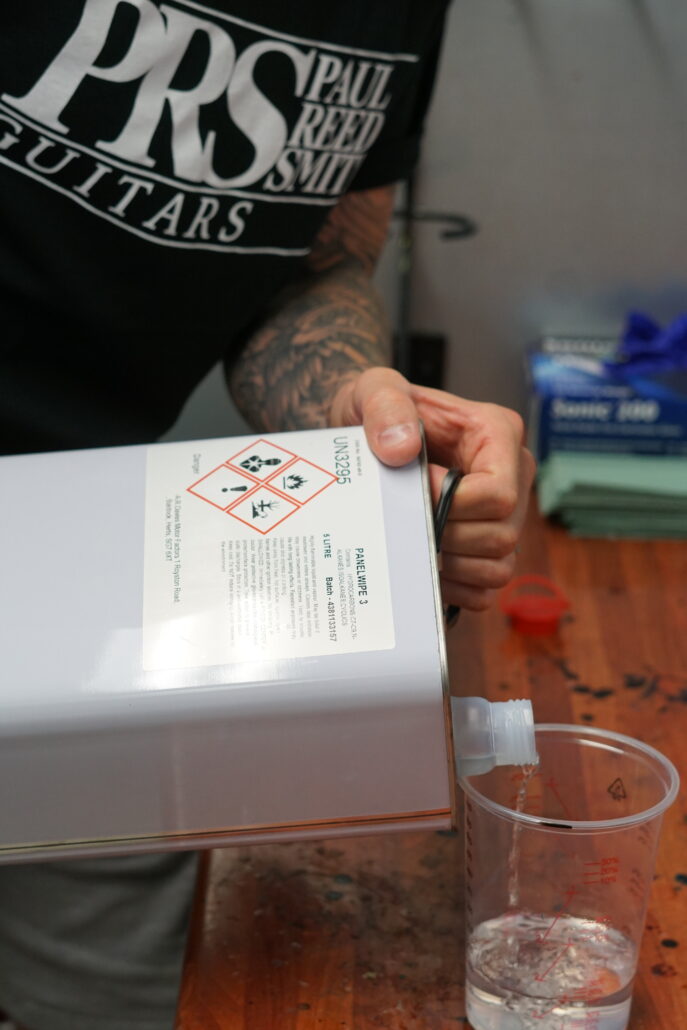

It is essential that Paint and Stains are mixed on day of use, so I will list what I need and check on finishes to be used. I also ensure the spray booth is cleaned before every job so I am ready to rock!

I am lucky to see all refinishing work through from start to finish. There are lots of projects at different stages, so one day I may be cutting and buffing finishes that I have previously sprayed and the other days I could be getting guitars disassembled ready for finish stripping.

2)What is your favourite PRS finish to do?

PRS have some of the best finishes in the business, Every finish is outstanding. My favourite finish to work with is the ‘Blue Fade’ stain. It is such a great colour and requires detailed workmanship to achieve the fades. I also love working with the ‘Eriza Verde’ as this produces such a good colour transformation once the stains are layered.

3)How long does the stain and finish process take?

All processes vary in time depending on stains used. Some require top sand outs and others may use different colour combination for the neck and body. Elongated curing times on finishes can prolong the process, the weather in the UK isn’t the most tropical, and a warm ambient temperature speeds up paint curing.

4)What’s been the most challenging PTC job you’ve worked on?

This is without doubt a ‘Dragon 2000 Ltd Edition’ which was sent in by a customer. It took me months and I mean months to complete. This had to be refinished back to original, the whole body stripped whilst ensuring the intricate and incredible inlay remained intact. I had to then colour match the body’s back and sides from pictures, mixing and test spraying samples. The top stain was a special colour mix which I had to reproduce in house. A final touch of precision airbrush shadow work was added. This project was akin to recreating a work of art, and I was honoured to be able to carry out such work on a masterpiece.

5)What made you want to go into guitar maintenance and repair?

From the age of 12 I have played guitar and always liked modifying my own. Have to say, I was pretty handy with a soldering iron and screwdriver even in the early days! I always liked designing and making things. I used to make radios from component kits and wooden boxes to store my pedals and guitar leads.

An old friend of mine who was in my first band somehow smashed his guitar, unsure how it was actually damaged, but he told his dad it fell off the wall hanger. I am sure there is more to it….

When the guitar returned from a local repair company it looked amazing, no damage and a killer paint job. At that exact moment I knew what I wanted to do and worked tirelessly to make that dream into a reality.

6) What’s your favourite PRS and why?

This has to be the Tremonti Signature with stop tail bridge. I was lucky enough to order this model for my employee guitar and oh my, what a guitar it is!. Fat body, slim neck and sounds outrageous. The sustain and clarity is like no other. I have an older SC245 so knew I had to get another singlecut as they produce such a full body tone.

7)What do you love the most about working in the guitar world?

I love that every day is different. I am always kept on my toes, there is always something new and interesting which pushes the boundaries. I love being hands on producing/repairing guitars for customers who appreciate the hard work and level of detail we at PRS Europe strive to achieve.